I. Industry introduction

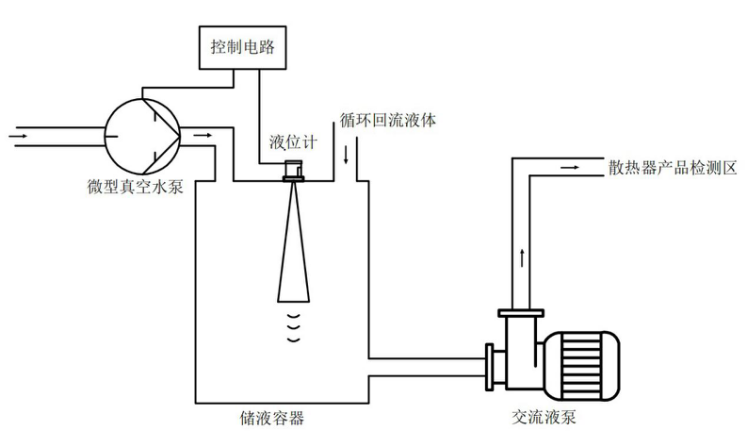

In an industrial environment that requires liquid cooling, a circulating pump is usually used to drive the coolant to flow in the pipeline. However, because the coolant evaporates and leaks over time, a small flow micro-liquid pump needs to be used to supplement the coolant in the liquid-cooled pipeline at any time. For example, in the metal radiator production industry, it is necessary to test the liquid cooling circuit to test the quality and effect of the radiator. The test liquid cooling circuit needs to add refrigerant as needed at any time, and the application of adding refrigerant liquid with small flow control can achieve precise control, more stable and reliable coolant replenishment.II. Introduction to the application of micro water pump

The liquid transportation in the factory is realized by the AC circulating pump as the core component of the pressurizing equipment, which can realize the circulation of high-pressure and high-flow cooling liquid and promote the circulation of the cooling liquid in the pipeline. However, it is not suitable as a cooling liquid supplementary pump.

In this scenario, a miniature vacuum water pump with a small flow rate and a high head is more suitable as a coolant refill pump. Combined with the on-site equipment process, under the control of the liquid level sensor and the PLC or the single-chip microcomputer, pumping can be started in time when the coolant is lower than the normal line and complete the liquid delivery and replenishment; the miniature vacuum pump developed by Chengdu Hilin Technology can quickly respond, easy to control, feedback and monitor real-time operating status. It is especially suitable for this application scenario that requires a combination of sensors and microcontrollers for automatic control to achieve precise micro amount fluid replenishment.

In this scenario, a miniature vacuum water pump with a small flow rate and a high head is more suitable as a coolant refill pump. Combined with the on-site equipment process, under the control of the liquid level sensor and the PLC or the single-chip microcomputer, pumping can be started in time when the coolant is lower than the normal line and complete the liquid delivery and replenishment; the miniature vacuum pump developed by Chengdu Hilin Technology can quickly respond, easy to control, feedback and monitor real-time operating status. It is especially suitable for this application scenario that requires a combination of sensors and microcontrollers for automatic control to achieve precise micro amount fluid replenishment.

III. Project Difficulties

1. Most of the miniature vacuum water pumps on the market cannot control the speed, and the change of the working load pressure on the site causes a large difference between the flow change and the expected value, which is not conducive good for the automatic control of liquid supplement.2. On-site use requires that the liquid pump can be "self-priming", can pump water when power is on, and it can be dry-running when no liquid is pumped.

3. It is necessary to suck liquid with a certain viscosity.

4. The factory equipment requires the miniature vacuum water pump to run continuously for 24 hours without electricity cut-off, long life, high stability, and maintenance-free.

IV. Solution

1. The S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology has a small output flow for general liquids, and the flow range: 0.2L/min~3L/min adjustable. The on-site connection of the PWM signal realizes the adjustment of the output flow and pressure, and has the function of the pump speed feedback signal, which is more in line with the actual on-site application.

2. The S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology is a liquid-gas dual-purpose type, which can be used as a liquid pump or a vacuum pump; it can run dry and can be self-priming. Before starting, there is no need to add water to the pump cavity, and directly suck the vacuum first and then pump the liquid.

3. The S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology is a dual-purpose type of liquid and gas pump. It can run dry to pump the container to a certain negative pressure, and the container directly sucks the liquid medium with a certain viscosity. .

4. S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology has low power and compact size. The premium version of the product can work continuously for 24 hours without power off. The service life as a water pump is more than 6000 hours, and the service life as a vacuum pump is more than 10,000 hours. Use DC 24V or DC 12V direct current voltage power supply, long-term use is stable, reliable and maintenance-free.

2. The S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology is a liquid-gas dual-purpose type, which can be used as a liquid pump or a vacuum pump; it can run dry and can be self-priming. Before starting, there is no need to add water to the pump cavity, and directly suck the vacuum first and then pump the liquid.

3. The S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology is a dual-purpose type of liquid and gas pump. It can run dry to pump the container to a certain negative pressure, and the container directly sucks the liquid medium with a certain viscosity. .

4. S series miniature vacuum water pump developed and produced by Chengdu Hilin Technology has low power and compact size. The premium version of the product can work continuously for 24 hours without power off. The service life as a water pump is more than 6000 hours, and the service life as a vacuum pump is more than 10,000 hours. Use DC 24V or DC 12V direct current voltage power supply, long-term use is stable, reliable and maintenance-free.