1. Background introduction

Surgical wounds, including wounds caused by various chemical, physical, mechanical, biological injury factors or surgery. The treatment of the wound is very important to the healing process. "Through debridement and open drainage" is the main principle followed by debridement, but traditional debridement methods have disadvantages such as low efficiency and incomplete debridement. With the development of science and technology, the multifunctional debridement machine is more efficient and more thorough than traditional debridement methods. At the same time, it reduces the damage to normal tissues during the debridement process and reduces the pain of patients.

2.Introduction of multifunctional debridement machine

The multifunctional debridement machine is a kind of cleaning medical equipment for complex wounds. It integrates ultrasonic cleaning, pulsation washing and negative pressure suction. It efficiently removes the necrotic tissue of the wound, and at the same time, it protects the new tissue, disinfects and sterilizes, and quickly wastes it. Liquid is drained to avoid secondary infection.

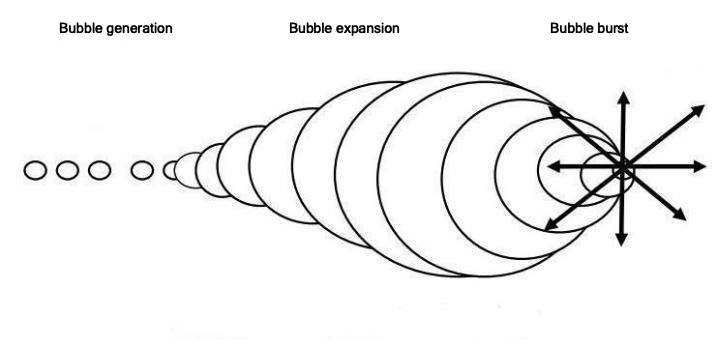

Ultrasonic cleaning: The cavitation effect of ultrasonic waves can produce many micro-bubbles when ultrasonic waves act on the washing liquid. These micro-bubbles expand and contract strongly with the ultrasonic vibration. When the bubbles collapse, they produce micro-jets and form an impact force. Bacteria and foreign bodies in the wound are removed, and at the same time, the necrotic tissue is detached and removed.

Pulse flushing: A pulse flushing fluid with a certain pressure is output through a micro-liquid pump to make the wound tissue surface alternate between contraction and diastole regularly. The thrust generated by the burst of water bubbles in the flushing fluid will contaminate the wound surface. Objects are loosely carried away by water currents. This type of debridement is mainly used for large-area open wounds.

Negative pressure suction: The above two debridement methods work alternately to quickly clean up the wound. In order to avoid the spread of infection and ensure that the healing environment is kept clean, the waste liquid is recycled by negative pressure suction.In addition, by creating a vacuum environment on the wound surface that is not conducive to bacterial growth, it can play a role in disinfection and sterilization and accelerate wound healing.

3.Application analysis of micro-pump debridement machine

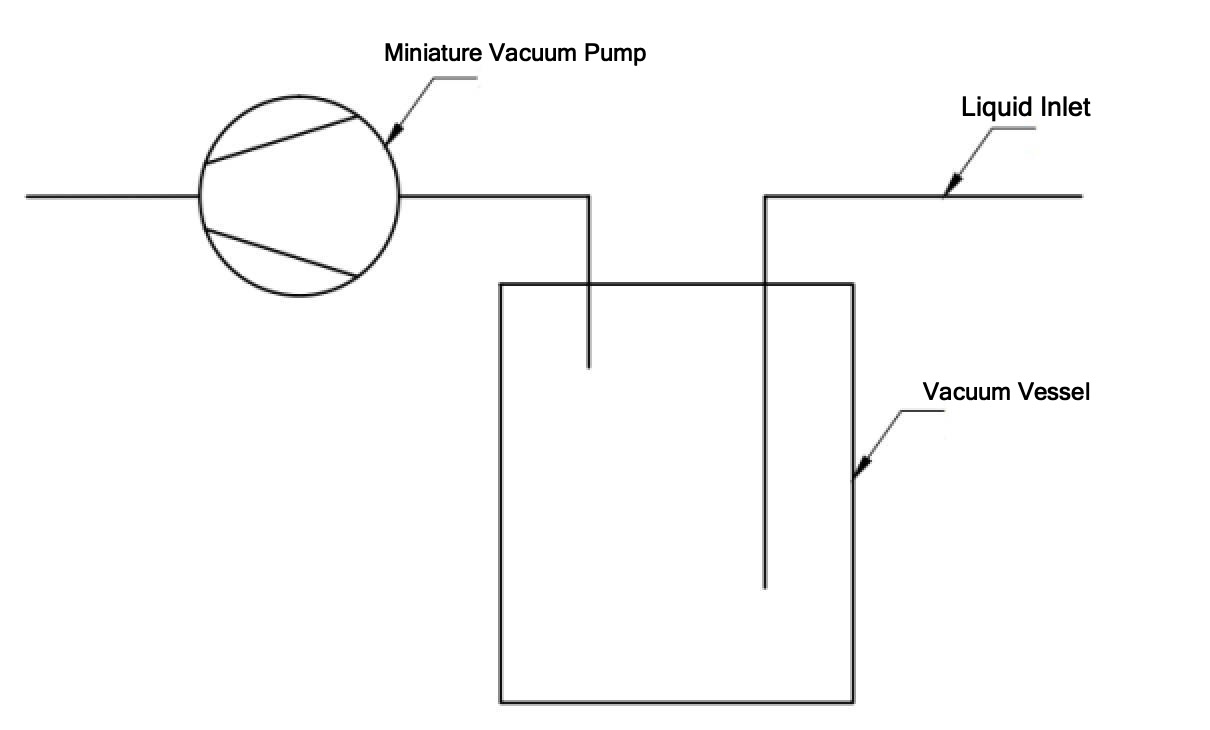

The micro-liquid pump is used in the ultrasonic cleaning process to transfer the cleaning liquid, and after ultrasonic cavitation, it is sprayed onto the tissue wound. During the pulse flushing, the flushing fluid is pressurized by the micro-liquid pump (generally the hydraulic pressure is about 55kPa). The miniature vacuum pump maintains a stable negative pressure environment for the negative pressure container during negative pressure suction. Why does not use the liquid pump to directly pump the waste liquid, but use negative pressure to indirectly attract the waste liquid? Because the waste fluid discharged from debridement contains complex mixed media such as cleaning fluid, blood and necrotic tissue, if it is pumped directly with the liquid pump, it is easy to block or corrode the pump body, and at the same time, to avoid cross-contamination caused by repeated use.

Application features:

1. In the two debridement process, a micro liquid pump is required to easily adjust the flow rate and have a certain anti-corrosion ability to complex media. The common cleaning fluid components for debridement are physiological saline and hydrogen peroxide;

2.In this application, the miniature vacuum pump used for negative pressure suction needs to have a relatively small volume while having both a high vacuum and a large flow rate. Four, product solutions

Recommendations for miniature vacuum pumps:

1. Miniature vacuum pump C50 series: (see product center for details) Model: C50L, C50S

Miniature diaphragm vacuum pump, brushless motor, remote control and speed regulation, relative vacuum (negative pressure) greater than -60kPa, no-load average flow range: 11/min~14.5L/min (test data of soap film flowmeter)

Advantages: long life, small volume and large flow, multi-function speed regulation.

2. Miniature vacuum pump C60L: (see product center for details)

Brief description:Miniature diaphragm vacuum pump, brushless motor, remote control and speed regulation, relative vacuum (negative pressure) greater than -88kPa, no-load average flow greater than 17.5L/min (test data of soap film flowmeter)

Advantages: long life, high vacuum, large flow, multi-function speed regulation.

3. Miniature vacuum pump C61: (see product center for details)

Brief description:Miniature diaphragm vacuum pump, brushless motor, remote control and speed regulation, relative vacuum (negative pressure) greater than -65kPa, no-load average flow rate greater than 26.5L/min (test data of soap film flowmeter)

Advantages: long life, high vacuum, large flow, multi-function speed regulation.

Product recommendations for micro liquid pumps:

1. Miniature liquid pump S36 series: (see product center for details) Model: S36L, S36M, S36S

Brief description: Miniature liquid diaphragm pump, brushless motor, gas-liquid dual purpose, rated working voltage 24V, no-load liquid flow range: 1.3-3L/min (S36L: 3L/min, S36M: 2L/min, S36S: 1.3L /min)

Advantages: stable flow, adjustable flow, high lift, compatible with complex media, remote control

2. Miniature liquid pump S23: (see product center for details)

Brief description: Miniature liquid diaphragm pump, brushless motor, gas-liquid dual purpose, rated working voltage 12V, no-load liquid flow rate: about 0.4L/min

Advantages: stable flow, small size, low noise, compatible with complex media, remote control