1. Background Introduction

Lasers-devices that can generate lasers. Since their advent in 1958, they have been rapidly iterated over several decades. Their functions have been continuously improved, their volume gradually reduced, and their components have become more sophisticated. They have been made in high-tech fields such as communications, medical, military, etc. Revolutionary breakthrough. The working medium can be divided into four categories: gas lasers, solid-state lasers, semiconductor lasers and dye lasers. At present, lasers are widely used in industrial manufacturing fields such as laser precision cutting, laser 3D printing, laser marking and laser etching.

2. Application Introduction

For gas lasers, the laser generator can produce light sources with different wavelengths according to the gas medium carried by the resonant cavity, and the uses are also different:

1. He-Ne laser: the most important red light source (632.8 nm)

2. Carbon dioxide laser: wavelength about 10.6 μm (infrared), important industrial laser

3. Carbon monoxide laser: wavelength of about 6-8 μm (infrared), only works under cooling conditions 4. Nitrogen laser: 337.1 nm (ultraviolet) 5. Mixed gas laser: does not contain pure gas, but a mixture of several gases (Generally argon, krypton, etc.)

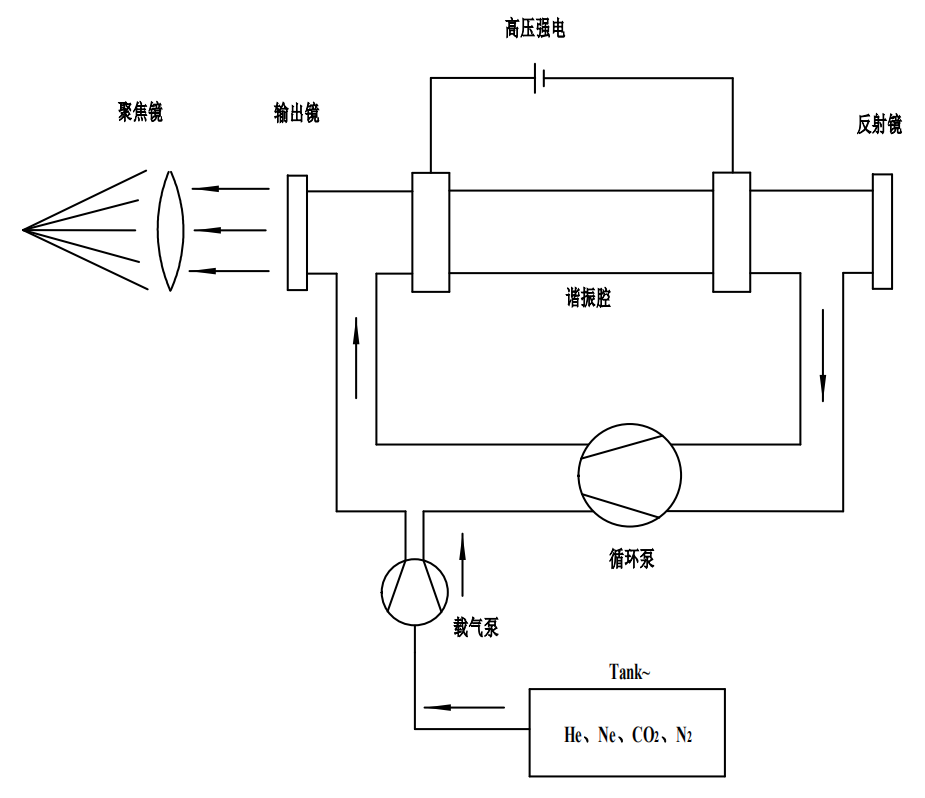

Taking carbon dioxide laser as an example here, it is a gas laser that uses CO2 gas as a working substance. The resonant cavity is filled with auxiliary gases such as CO2, He, and N2. Under the action of a circulation pump, it continuously reciprocates in the pipeline through Apply a strong voltage to the resonant cavity to form a current. During the discharge process, the N2 molecules in the cavity are excited by the impact of electrons, collide with the CO2 molecules, and transfer energy to the CO2 molecules. The CO2 molecules transition from the low energy level to the high energy level and are released. The photon is emitted. Under the joint action of the reflector and the output mirror in the resonant cavity, the photon transfers energy to more CO2 molecules, so that more other CO2 molecules enter the mass emission state, releasing more photons to form a laser.

1. Carrier gas process: the working medium and auxiliary gas to be excited are sucked through the diaphragm pump and loaded into the pipeline.

2. Circulation process: The gas circulation inside the pipeline is realized through the diaphragm pump to ensure that a sufficient number of CO2 molecules effectively transition to produce a stable laser.

As a carrier gas circulation pump, the miniature air pump is equivalent to the power for driving gas to circulate and circulate in the laser, and needs to meet various requirements for gas circulation under the working state of the laser.

3. Difficulties of the project

1. Does not pollute the loaded gas medium, does not contain oil and other impurity components, to avoid interference of other molecules into the resonance cavity.

2. The circulation pump needs to maintain a stable flow rate and pressure during the use of the equipment to obtain stable fluid transmission, and it must not pollute the gas medium, and has high stability

3. The carrier gas pump and circulating pump require extremely high air tightness to ensure that the gas leakage rate is at a very low state.

4. Long life, ideally, the working life of the micro pump needs to be greater than or equal to the working life of the laser, in order to achieve maintenance-free and replacement-free during the entire life of the laser.

4.Solutions

D23 series micropump

Uses: Used as a carrier gas pump and a circulation pump to supply gas to the system and circulate the gas in the pipeline.

Brief description: The micro pump pump can generate negative pressure at the suction port, suck in gas, and apply a positive pressure at the exhaust port to discharge gas. It is suitable for sampling, gas circulation and other scenarios.

advantage:

1. Small size, stable flow rate, moderate positive and negative pressures, fiber reinforce nylon and EPDM rubber materials, good resistance to corrosive gases and radioactive gases;

2. The use of interference-free brushless motor will not affect other EMC sensitive components of the equipment;

3. Both the suction port and the exhaust port can be loaded with full rated load, and the double sealing method is adopted, the leakage rate is low, and the air tightness is good;

4. Using magnetic silencing technology, low running noise, stable performance, high parameter consistency, long life, continuous working life can reach more than 10000 hours.