1. Background

In some laboratory chemical experiments, chemical plant waste liquid discharge index detection or water quality monitoring, some experiments require sampling, collection or transmission of corrosive, chemical reaction with the transmission equipment materials, or does not allow polluting media When the liquid sample is used, the traditional liquid pump can no longer function normally. Especially when you need to transfer or collect high-temperature liquids, corrosive liquids, oily liquids, liquids with solid impurities, and high-viscosity liquids, these liquid media need to pass through the liquid pump when using traditional liquid pumps, which may cause damage to the liquid pump, so use The vacuum principle transfers the liquid medium indirectly. If the medium does not pass through the pump, the tolerance range for the type of medium can be greatly expanded.

2. Application Introduction

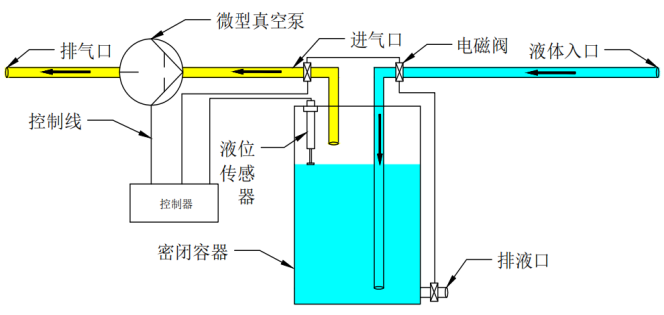

If a micro-vacuum pump is used to drive a closed container to form a vacuum system to generate negative pressure to collect and transport liquid, this will avoid direct contact between the pump and the experimental medium and does not occupy installation space. A control unit can also be added to the entire vacuum system, which can not only control the start and stop of the system, but also accurately control the amount of collected samples.

1. Principle description:

(1) The sealed container is driven by a micro vacuum pump to generate negative pressure to draw liquid into the container;(2) Connect the control line of the pump (such as PLC, single-chip microcomputer and other control units) with the control line of the pump, liquid level sensor and solenoid valve to control the amount of sample collected by the container;

(3) The solenoid valve of the discharge port can be controlled by the controller to discharge the collected liquid.

2. Application scenario description:

This method is suitable for the extraction of oily, corrosive, and solid-liquid mixed liquids. It is not suitable for the scenario of direct extraction by liquid pumps. For the extraction of clean water or other non-corrosive, low-viscosity liquids, S series and W series liquid pumps can be used.

3. Notes on matters needing attention:

(1) The selected closed container needs to have a certain ability to withstand negative pressure, and it is best to have a discharge channel at the bottom of the container;(2) The selected liquid level sensor needs to have certain corrosion resistance, and some use scenarios must not contaminate the medium, etc.

3. Difficulties of the project

1. The micro vacuum pump needs to have a relatively small volume and at the same time have a higher vacuum degree and a larger flow rate;2. The micro vacuum pump needs a convenient speed regulation function, which can quickly and accurately adjust the flow rate;

3. It is required that the micro vacuum pump has the function of remote control start and stop;

4. The micro vacuum pump needs to work continuously for a long time and have a long life。

4.Solutions

1. Hilin Technology's C series micro vacuum pumps maintain a small volume while also having a higher vacuum and a larger flow rate. For example: the volume of the micro vacuum pump C50L is 134×96×80, the relative vacuum degree is above -61KPa, and the flow rate is above 14.5L/min;

2. Each model of Hilin Technology's C series micro vacuum pump has a version with speed control function. The pumps have various speed adjustment methods, and customers can choose different speed adjustment versions according to their own use. For example: In addition to the simplified version without speed regulation, the mini vacuum pump C30L has a speed regulation function. It has a knob speed regulation type that realizes speed control through an external knob encoder, a frequency speed control type that realizes speed regulation by adjusting frequency signal, There is also a top matching type that adjusts the speed through the touch screen, and the top matching type not only supports touch speed adjustment but also supports remote frequency speed adjustment;

3. Hilin Technology's C series miniature vacuum pumps have undergone rigorous life testing. Each model is divided into roughly three versions according to life and performance: "simplified version, standard version, and quality version". The quality version of some models has a continuous working life of 10,000 hours. The life test conditions of the micro vacuum pump: "In a clean and non-corrosive laboratory, the pump is fully loaded (the exhaust port is blocked, the exhaust port is open to the atmosphere), and runs continuously around the clock; ambient temperature: 5 ℃ ~ 33 ℃, depending on the climate Fluctuations; relative humidity 30% to 90%, fluctuating with the climate.".

4. Some models of Hailin Technology's C series micro vacuum pumps have added remote start and stop control ports, combined with the situation of the user's field control unit to realize remote control of the start and stop of the vacuum pump, such as: C50, C60.